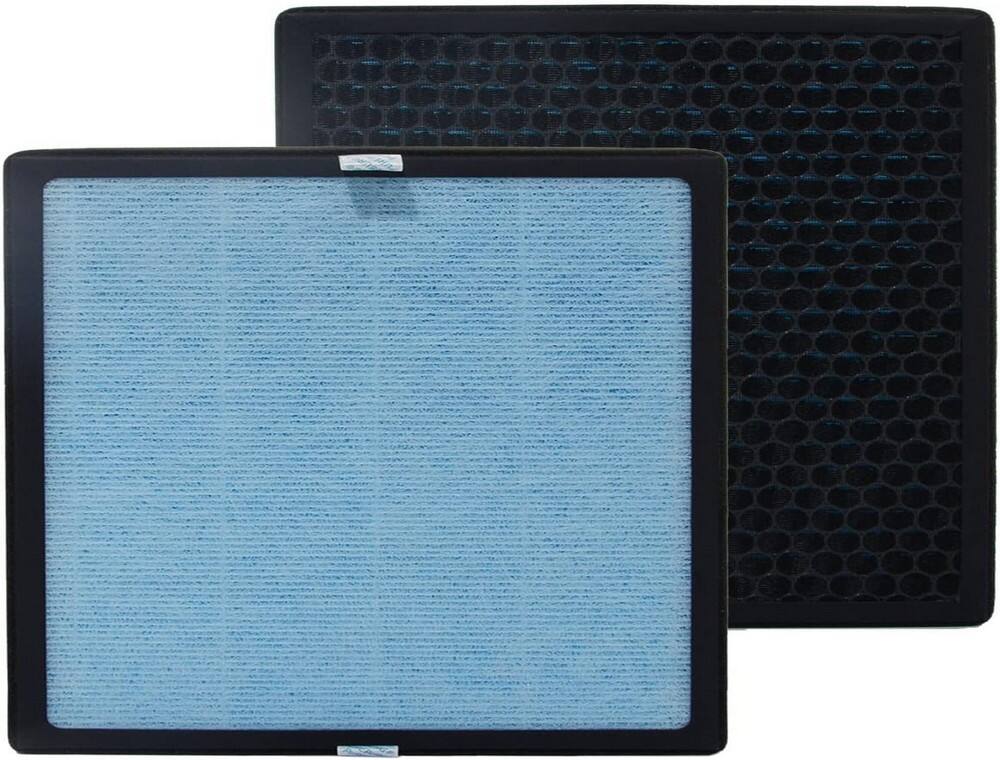

Deep Pleated Paper Separate H14 High Efficiency HEPA Air Filter

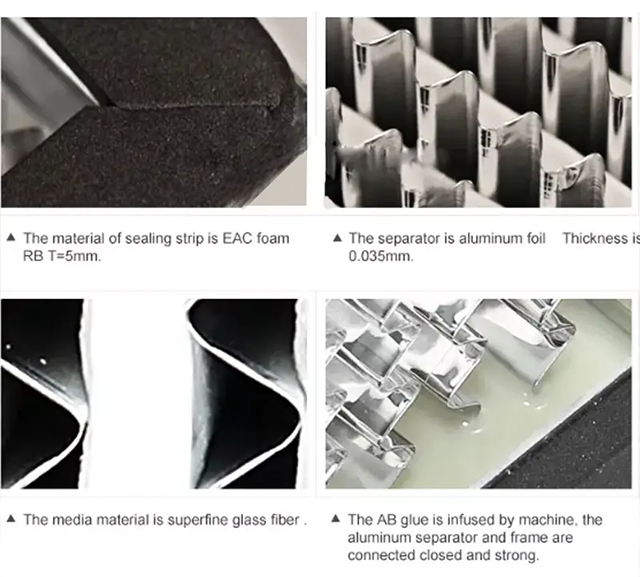

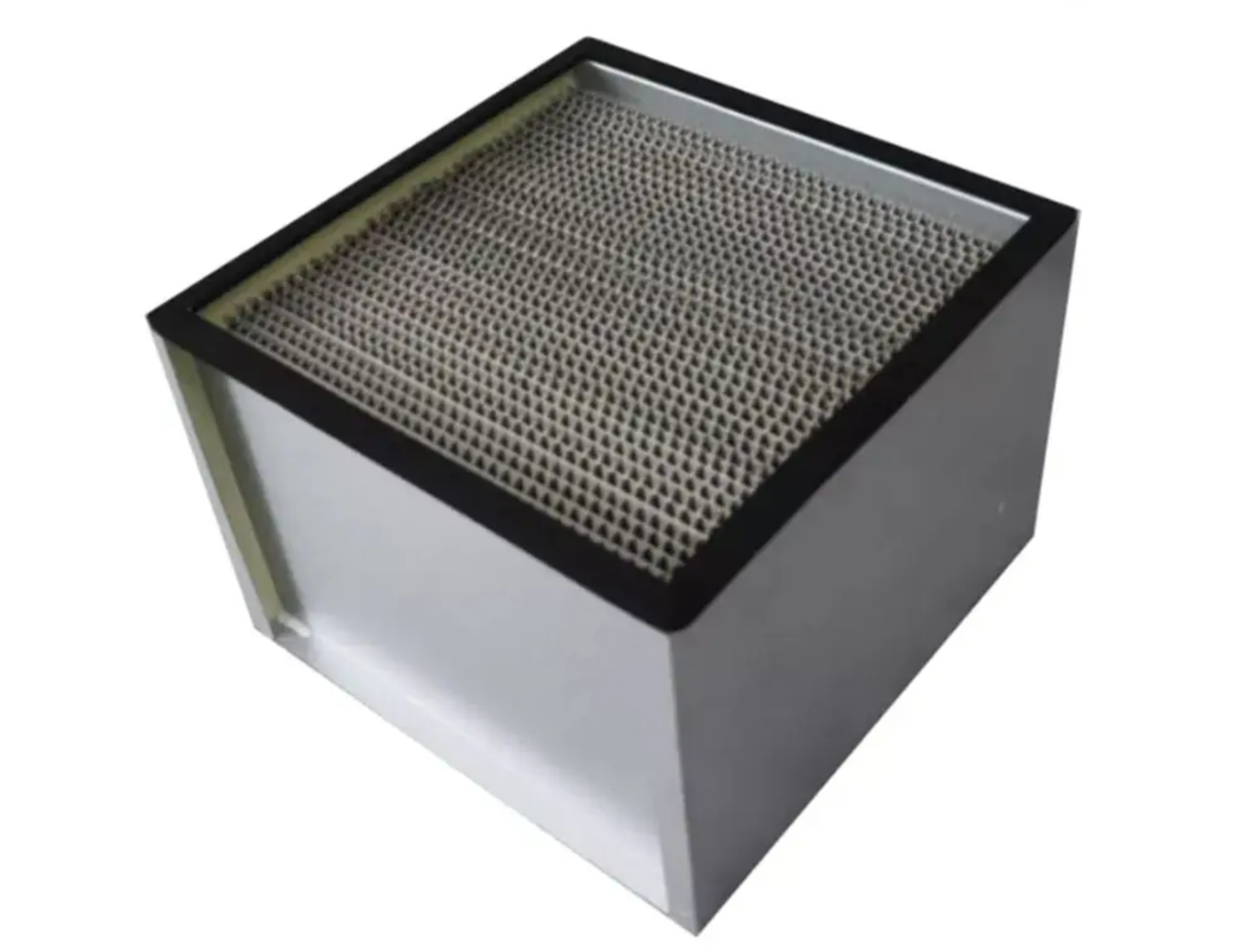

Deep Pleated Hepa filter is the final filtration in a clean room, designed to filter particles larger than 0.3um. It uses ultra-thin glass fiber as the filter media and hot-melt glue to space each pleat evenly, ensuring high dust volume efficiency. The entire media area can be utilized effectively.

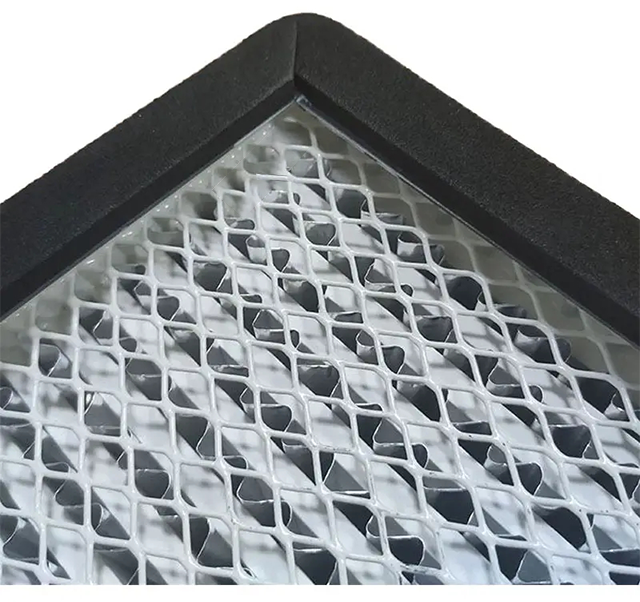

1. To prevent the bypass of unfiltered air, deep pleated HEPA filters are equipped with gaskets or seals along the perimeter of the frame. These seals ensure a tight fit within the filter housing and minimize leakage.

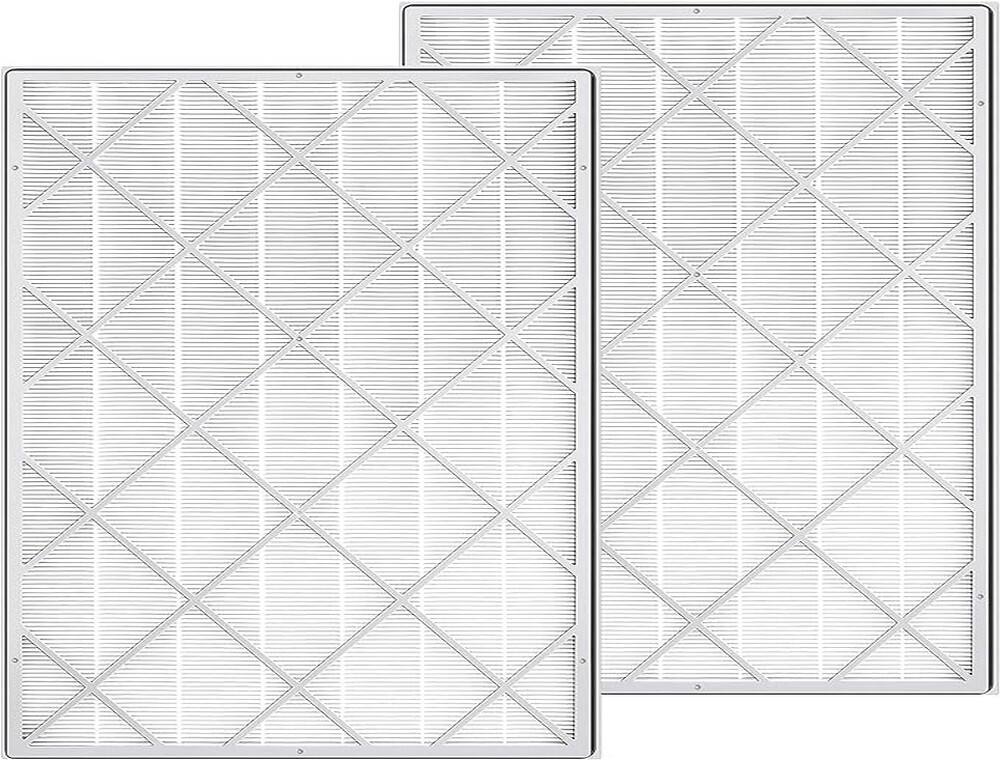

2. The deep pleats in the filter media facilitate the interception, impaction, and diffusion of airborne particles, ensuring thorough filtration and clean air output.

3. The compact design of deep pleated HEPA filters allows them to fit into standard filter housings or air handling units without compromising airflow performance

- Overview

- Parameter

- Inquiry

- Related Products

The deep pleated compact filter is a high-efficiency air filtration device suitable for various high-demand air filtration environments. Its deep pleat design greatly increases the filtration area, thereby improving filtration efficiency and service life. This filter is compact and easy to install and replace. Its excellent filtration performance can effectively remove particles in the air and ensure air quality. In addition, deep-pleated compact filters offer low operating costs and simple maintenance, making them ideal for high-efficiency air filtration.

High-efficiency filter (HEPA) generally refers to the particle size greater than or equal to 0.3um particles of the capture efficiency of 99.97% or more of the filter, usually as a pharmaceutical company clean room end filtration devices, to provide clean air. Whether the clean room can reach and maintain the designed clean level is, to a certain extent, related to the performance of high-efficiency filters and their installation. Therefore, leak testing of HEPA filters in cleanrooms to ensure compliance is one of the most important means of ensuring a clean environment in a cleanroom, and the FDA has also pointed out in the Guidelines for the Manufacture of Sterile Drugs that leak testing should be performed after the installation of HEPA filters to check the sealing of the filter gasket, frame and filter media, etc. Leak testing of HEPA filters should be performed periodically in sterile preparation production plants.

FEATTURES

● High-capacity

● 99.97%, 99.99%, and 99.999% efficiency options available in moisture-resistant media

● One-piece seamless urethane gasket for leak-free sealing

● Sturdy structure

● Frame: galvanized/Aluminum steel frame for durability

● Filter: Fiberglass

APPLICATIONS

Deep pleated Hepa filters are essential for critical applications in healthcare, science, and high-tech manufacturing that demand the highest air filtration standards. These filters are produced with utmost precision and cater to various settings such as clean rooms, hospital operating theatres, biological containment labs, laminar flow clean benches and safety cabinets, food processing plants, and research laboratories.

Deep-pleat HEPA filters are engineered to offer an optimal blend of high filtration efficiency and superior dust-holding capacity. They feature a deep pleat pack of filter media, enclosed in either a corrosion-resistant coated mild steel or MDF case.

These filters are designed for air intake and extraction systems in critical environments such as pharmaceutical and electronic manufacturing, as well as hospital and research laboratories, where high-efficiency filtration is essential. They are also employed in safe change systems. Typically used as final filters, they are preceded by pre-filters to extend their lifespan.

SPECIFICATIONS

| Type | Size(mm) | Rated Airflow(m³/h) | Filter Class(m2) | Initial Pressure Drop(Pa) | Final Pressure Drop(Pa) | Average arrestance |

| HF-YGB | 484x484x150 | 530 | 6 | <220 | 400 | >99.97% |

| 610x610x150 | 1000 | 9.7 | <220 | 400 | >99.97% | |

| 1220x610x150 | 2000 | 19.3 | <220 | 400 | >99.97% | |

| 484x484x220 | 1000 | 9.8 | <220 | 400 | > 99.97% | |

| 610x610x220 | 1600 | 15.8 | <220 | 400 | >99.97% | |

| 1220x610x220 | 3000 | 31.6 | <220 | 400 | >99.97% | |

| 610*610*292 | 1700 | 17.6 | <220 | 400 | >99.97% | |

| 1220*610*292 | 3400 | 33.6 | <220 | 400 | >99.97% |

PRODUCT DETAILS